Thinner

1. Introduction & Definition

Thinners, also known as diluents or solvents, are volatile liquid formulations used to reduce the viscosity of paints and coatings. They are essential for adjusting application properties, controlling drying times, and achieving the desired final film characteristics. An effective thinner dissolves the paint’s resin system, transforming a concentrated product into a workable state suitable for spraying, brushing, or rolling.

2. Types of Thinners

Thinners are formulated to be chemically compatible with specific paint systems. The primary types include:

-

For Water-based Paints (Acrylic/Latex): Water is the primary diluent.

-

Oil-based Thinner: Formulated for alkyd resin-based paints.

-

Quick-Drying Thinner: Designed for nitrocellulose-based lacquers.

-

Epoxy Thinner: Compatible with epoxy coating systems.

-

Polyurethane Thinner: For use with polyurethane paints.

-

Oven Thinner (Baking Enamel Thinner): For stoving or heat-cured enamels.

-

Traffic Thinner: For road marking and traffic paints.

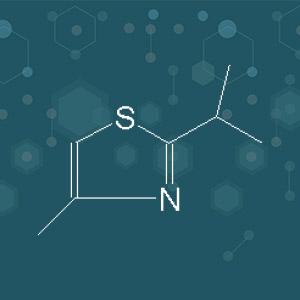

In essence, most thinners are not single solvents but precise blends of several solvents designed to optimize performance.

3. Key Functions & Performance Criteria

A high-quality thinner must meet several key performance criteria:

-

Drying Speed: Governed by the evaporation rate of the solvent blend.

-

Film Formation: A suitable thinner ensures a smooth, uniform, and optically clear film without defects like orange peel or blushing.

-

Adhesion: It must properly dissolve the paint to promote strong inter-coat adhesion.

-

Gloss: It should not negatively affect the final gloss level of the coating.

-

Viscosity Control & Sprayability: It adjusts the paint for optimal application using spray equipment.

The quality and price of a thinner are directly related to the proportion and purity of its primary solvents. High-grade thinners contain a higher concentration of active solvents, yielding superior performance.

4. Production Method

Producing high-quality thinner requires precise formulation and strict quality control. The process begins with creating a base, which is blended with specific petroleum-derived solvents. The mixture then undergoes a critical maturation period (e.g., 21 days) to ensure stability and homogeneity. After this period, the batch is rigorously tested in a laboratory. If it fails to meet specifications, the formulation is revised. Only approved batches are approved for packaging and distribution.

5. Common Applications

The primary use of thinners is to dilute paints and coatings for application. They are also widely employed for cleaning application tools like brushes, rollers, and spray equipment, and for removing paint from surfaces.

6. Safety and Environmental Considerations

Thinners are flammable, volatile, and hazardous materials that require careful handling.

-

Flammability: The flash point determines the fire hazard and dictates requirements for storage, transportation, and use.

-

Health Hazards:

-

Inhalation: Vapors can cause respiratory tract irritation, dizziness, central nervous system depression, and irreversible organ damage. Use only in well-ventilated areas with appropriate respiratory protection.

-

Skin Contact: Can cause irritation and defatting, leading to dermatitis. Chemical-resistant gloves are mandatory.

-

Eye Contact: Causes severe irritation, redness, blurred vision, and potential tissue damage. Safety goggles must be worn.

-

-

Environmental Impact: As hazardous chemical waste, thinners must never be disposed of into the environment. They require proper containment and disposal according to local regulations.

7. Corporate Profile: Atlas Exirsazan Company

As part of its commitment to quality, Atlas Exirsazan Company produces a wide range of thinner grades, establishing itself as a leading manufacturer in Iran and the Middle East. Building on its dominant position in domestic markets, the company has successfully expanded its export network, with dedicated sales operations in key regional markets including Iraq, the UAE, Afghanistan, and Pakistan. It is now ranked among the top exporters of chemical products in the region.